* Please refer to the English Version as our Official Version.

* Please refer to the English Version as our Official Version.

In recent years, with the guidance of policies and the strong support of capital, the development of silicon carbide industry in my country has accelerated sharply, and a large number of people such as Tianke Heida, Tianyue Advanced, Han Tiancheng, Dongguan Tianyu, and Taico Tianrun Outstanding silicon carbide enterprise with independent intellectual property rights.With the rise of these enterprises, the technology gap in silicon carbide in China has gradually reduced the technology gap with developed countries.

Recently, the reporter of the "Entering the Industrial Chain" column of Xinzhiya interviewed Yang Chengjin, chairman of Shenzhen Sen Guoke Technology Co., Ltd. (hereinafter referred to as "Sen Guoke"), a rising emerging company in the silicon carbide device industry, Yang ChengjinIn the context of low -carbon and double -carbon era, the development of the current enterprise of Sen State and the outlook on the silicon carbide industry.

Product counterparts of large abroad factories, silicon carbide diode has been shipped in large quantities

It is understood that Mori State is a national high -tech enterprise specializing in the design and sales of silicon carbide (SIC) power device.The current fifth -generation 650V and 1200V TMPS (Thinned MPS) silicon carbide Schotki diode has been strictly verified by the market, with a yield of more than 97%.Energy storage inverters, new energy vehicles, charging piles, mining machine power and other large fields.& nbsp;

Typical application scenarios of silicon carbide diode

Source: Mori Guoke

"Actually, Mori State has decided to do silicon carbide rate devices since 2018. Prior to this, the company mainly focused on Vision-Adas (high-end auxiliary driving) and brushless motor-driven chip." Yang Chengjin Jin JinjinThe third -generation semiconductor silicon carbide devices such as low loss have become the development trend of power devices. "

The reporter learned that although Mori State started late in the field of silicon carbide, with a keen market sense of smell, the huge consumer electronics market cut into the large -power fast -charging head, which quickly opened the market for the application of silicon carbide.

Yang Chengjin pointed out: "In recent years, in order to solve the user's charging anxiety and the pursuit of the highest volume energy efficiency ratio, the charging head manufacturer has begun to use GAN MOS and SIC diodes as energy efficiency conversion devices.20 to 3 billion branches, if they are all used in SIC diode, it will form a demand for silicon carbide power devices of more than 10 billion yuan. "

After long -term research and development and repeated verification, Mori State launched KS04065 (650V/4A), KS06065 (650V/6A), KS08065 (650V/8A), and KS10065 (650V/10A) for KS04065 (650V/4A), KS06065 (650V/6A), Different packaging of more than a dozen models of silicon carbide diode products.It is worth mentioning that these dozen products are not inferior to foreign manufacturers in terms of specific performance parameters, and can provide different packaging forms according to the selection requirements of different partners.

Take the KS06065 product as an example. The product is 650V, the forward current is 6A, the highest working temperature is 175 ° C, and the PDFN5*6 packaging is used.Charging the electrolytic capacitor when starting.It is currently applied to the 240W nitrogen -nitride travel fast charging of EGO EXINNO and the power module of Rui Shijia 240W dual -C port.

"Our products have been shipped in large quantities in the consumer market consumer market. At present, there are more than 100 customers in cooperation, including well -known consumer electronics companies such as Lixun and Green Union.Low VF, High BV and other excellent product characteristics and high cost -effectiveness have received widespread praise from downstream partners. "Yang Chengjin emphasized.

In addition to consumer electronics, photovoltaic is also one of the important application scenarios of silicon carbide devices.As the photovoltaic industry enters the era of "large components, large inverters, large span stents, and large groups", the voltage level of photovoltaic power stations has been increased from 1000V to more than 1500V, and silicon carbide power devices must be used to improve the conversion efficiency and reduce the system.cost.According to data from Casa Research, the proportion of silicon carbide power devices in photovoltaic inverters in 2020 is 10%, and the proportion of silicon carbide photovoltaic inverters in 2025 will reach 50%.

Yang Chengjin said that the status of silicon carbide diode in photovoltaic power generation is very important and plays an important role in the PFC circuit of the inverter unit.For the photovoltaic inverter market, the company has successively launched the 1200V series of silicon carbide diode KS10120 (1200V/10A, KS20120 (1200V/20A), KS30120 (1200V/30A), KS40120 (1200V/40A) and other products.The standard of JEDEC's reliability experiments, performed well in the Double 85 experiment, can achieve perfect replacement of similar products of international mainstream brands.

The rapid development of new energy vehicles drives silicon carbide demand blowouts, and car -level silicon carbide products will soon be promoted to the market

If the fast charging head and photovoltaic are only "front dishes", then new energy vehicles are the "main dish" of silicon carbide.

As we all know, driven by the "new fourizations" of new energy vehicles networking, electrification, intelligence, and sharing, new energy vehicles have maintained high -speed growth in both production and sales.According to data from the Ministry of Industry and Information Technology, the cumulative production and sales of new energy vehicles in my country in the first half of 2022 completed 2.661 million and 2.6 million, respectively, an average of 1.2 times year -on -year, and the market penetration rate was 21.6%.

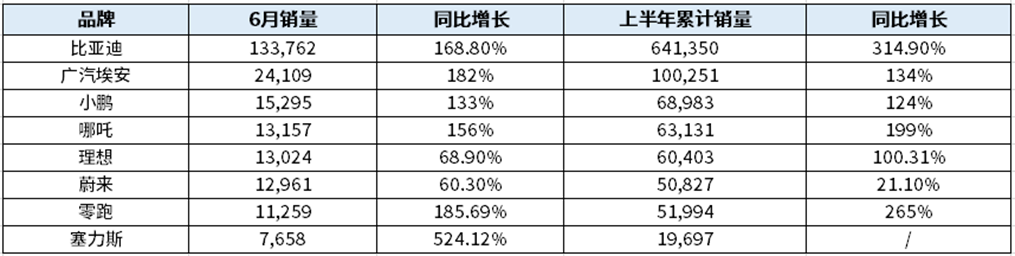

From the perspective of specific sales, BYD was the first in the first half of this year with a sales volume of 641,400 units. After GAC Ean was close to BYD with 100,300 vehicles, Xiaopeng ranked third with 690,000 vehicles; the growth rate; the growth rate; the growth rate;In addition, in addition to Weilai Automobile, new energy vehicle manufacturers have basically achieved double growth, especially BYD's growth rate, reaching a high growth rate of 314.90%.The car of the car in the current market is popular.

In the first half of 2022, the main sales volume of major new energy vehicle manufacturers in my country

Source: Core Eight Brother Organization

Yang Chengjin pointed out: "The largest application market for silicon carbide is new energy vehicles, and its proportion has exceeded 50%. The market size is expected to increase from 1.46 billion yuan in 2020 to 16.47 billion yuan in 2024, with an average annual compound growth rate of 83.2%. The application of silicon carbide power device involved in the new energy vehicle system architecture includes: motor drive system, vehicle charging system (OBC), power conversion system (vehicle DC/DC), and non -vehicle charging piles.The main inverter in the motor drive system can significantly reduce the volume, weight and cost of the power electronics system, and increase the power density; applied to the vehicle charging system and the power conversion system, which can effectively reduce the switching loss, increase the temperature of the limit, increase the temperature, increase the improvementSystem efficiency; while using new energy vehicle charging piles, the volume of charging piles can be reduced and the charging speed can be reduced. "

In fact, the reason why silicon carbide can be used on new energy vehicles is determined by its material characteristics.Because silicon carbide materials have excellent characteristics such as high frequency resistance, easy heat dissipation, high current density, low power loss, etc., it can just solve the pain points of demand points such as lightweight, range, and high -level requirements for new energy vehicles.

"The main factors that previously affected the mass production of silicon carbide devices were the problem of high cost. Slowly, with the decline of the wafer production and manufacturing cost and the price difference between silicon -based devices, considering the cost savings, space saving, and electric drive system performance of the heat dissipation systemIncreasing the added value such as improving the value of the vehicle, the market expressiveness of silicon carbide devices is becoming more and more superior. "Yang Chengjin analyzed.

The reporter noticed that the car -level silicon carbide diode developed by the Mori State Science and Technology has now been in the customer testing and certification stage.In addition, the company plans to launch a car -level SIC MOSFET product in the second half of 2022, and at the same time complete the pre -research of the silicon carbide module to create a rich and diverse product series to meet the diverse needs of customers.

Yang Chengjin said: "The Mori State has been deeply cultivated in automotive electronics for many years, and has accumulated rich technology and experience in the automotive field. Due to the fact that the silicon carbide market has just developed, the gap between various enterprises is not so large.Driven, the market of silicon carbide power devices will also usher in explosive growth. SIC MOSFET products of Mori State will soon be promoted to the market. It is expected to catch up with this wave of new energy vehicles. "

Failure to cultivate internal skills, rather than waiting for the wind to wait for the wind

In the silicon carbide industry, it is currently an oligopoly monopoly situation.Among them, Wolfspeed (CREE), as a global leading silicon carbide enterprise, has a market share of more than 60%, the market share of the device is nearly 30%, and the technology technology of multiple industrial chain links is the world's leading.In the field of silicon carbide, China currently has a market share of less than 10%, and it is initially estimated to lag behind the 1-2 generations of leading enterprises.

At present, the technical development of silicon carbide products at home and abroad

Source: Core Eight Brother Organization

How to avoid being stuck in the stuck is a question that every domestic power device manufacturer should think about.Especially for design companies operating light assets, product upgrades and technical iterations are relatively fast. Continuous R & D investment, technological upgrades and new product development are important means to maintain competitive advantages.

"Since the establishment of the Mori State, it has attached great importance to R & D investment. At present, the company's R & D personnel account for more than 70%, and the degree of graduate degree or above account for 50%. R & D personnel are mainly from MediaTek, Hisilicon, BYD Microelectronics, Rom, and other institutions.Including well -known universities such as Tsinghua University, Northwestern University of Technology, University of Electronic Science and Technology, Xi'an University of Electronic Science and Technology, "Yang Chengjin said.

In addition, the company is actively responding to the national call and continuously strengthened cooperation with the industry -university -research cooperation with well -known colleges."Now many scientific research institutions have done research and development topics of new technologies or new products, but because of their lack of market -oriented operating experience, it cannot become a market -oriented product to monetize. This is a pity. Therefore, through our effortsActively promote close cooperation with colleges and universities to help speed up the technical and products of these laboratories, hoping to create more value and significance for society. "Yang Chengjin further added.

In order to accelerate the development process of product research and development and increase market development, Mori Sciences completed the C round 100 million yuan financing in the second half of 2021.According to the company, the financing has received a warm response from the capital market.Industry Co., Ltd..In addition, Mori State shareholders also include Series A and B -round B -shares Northeast SAIC Investment, Lan Si Technology, First Entrepreneurship Securities, and Yueke Xintai Equity Fund.The shareholders of the new and old institutions cover the top domestic investment institutions, the state -owned background fund, and the capital capital of the industry.

Talking about the company's future development plan, Yang Chengjin pointed out that the third -generation technology of the R & D technology of SIC MOSFET SIC MOSFET is a flat process.Its 650V, 1200V, and 1700V series SIC MOSFET is expected to send samples to customers in Q3 in 2022, and large -scale mass production is expected to begin in 2023.

Mori State Science and Technology Silicon Carbide Product Planning

Source: Mori Guoke

In the post -epidemic era, consumer electronics demand continued to be sluggish, and the supply of vehicle regulatory chips was in short supply. Many car companies announced a temporary suspension of production or reduction of production due to the shortage of car chips.

Facing the market conditions of the overall structural differentiation of the semiconductor industry, Yang Chengjin said: "The semiconductor industry is a typical cyclical industry. Since I joined the industry for more than 20 years, I have experienced various cycles of large and small.Choose a contraction front during the trough period and expand the choice of climax in the industry. Although it looks understandable, there is a certain problem in actual operation. Because the semiconductor research and development cycle is long, it takes a lot of consumption from product definition to the final mass production listing.The time, when your product is pushed to the market, the prosperity may have passed. Therefore, our strategy of our Forestry State is that even in the trough of the industrial chain, we must continue to increase research and development into cultivation in internal skills, because the industry is industrial because the industry is industrial, because the industry is industrial, because the industry is industrial, because the industry is industrial, because the industry is industrial, because the industry is industrial, because the industry is in the industry, because the industryThe cycle will always come back, rather than waiting for the wind. "

Conclusion

At present, silicon carbide power semiconductor foreign wafers have developed from 6 inches to 8 inches, and domestic wafers develop from 4 inches to 6 inches, followed by the pace of development.With the further maturity of the upstream materials and wafers, the cost of silicon carbide power devices will decrease significantly, and the spring of silicon carbide power devices in my country has come.

Relying on the technical precipitation of the semiconductor industry for many years, Mori State Sciences has supported the accumulation of accumulation in the semiconductor industry and the support of well -known domestic and foreign supply chain partners.In the future, with the upgrading of the mass production and core technologies of car -level silicon carbide power devices, I look forward to creating more glory that is of their glory in the air outlet of the times and becoming a leader who leads domestic chips to globalization.