* Please refer to the English Version as our Official Version.

* Please refer to the English Version as our Official Version.

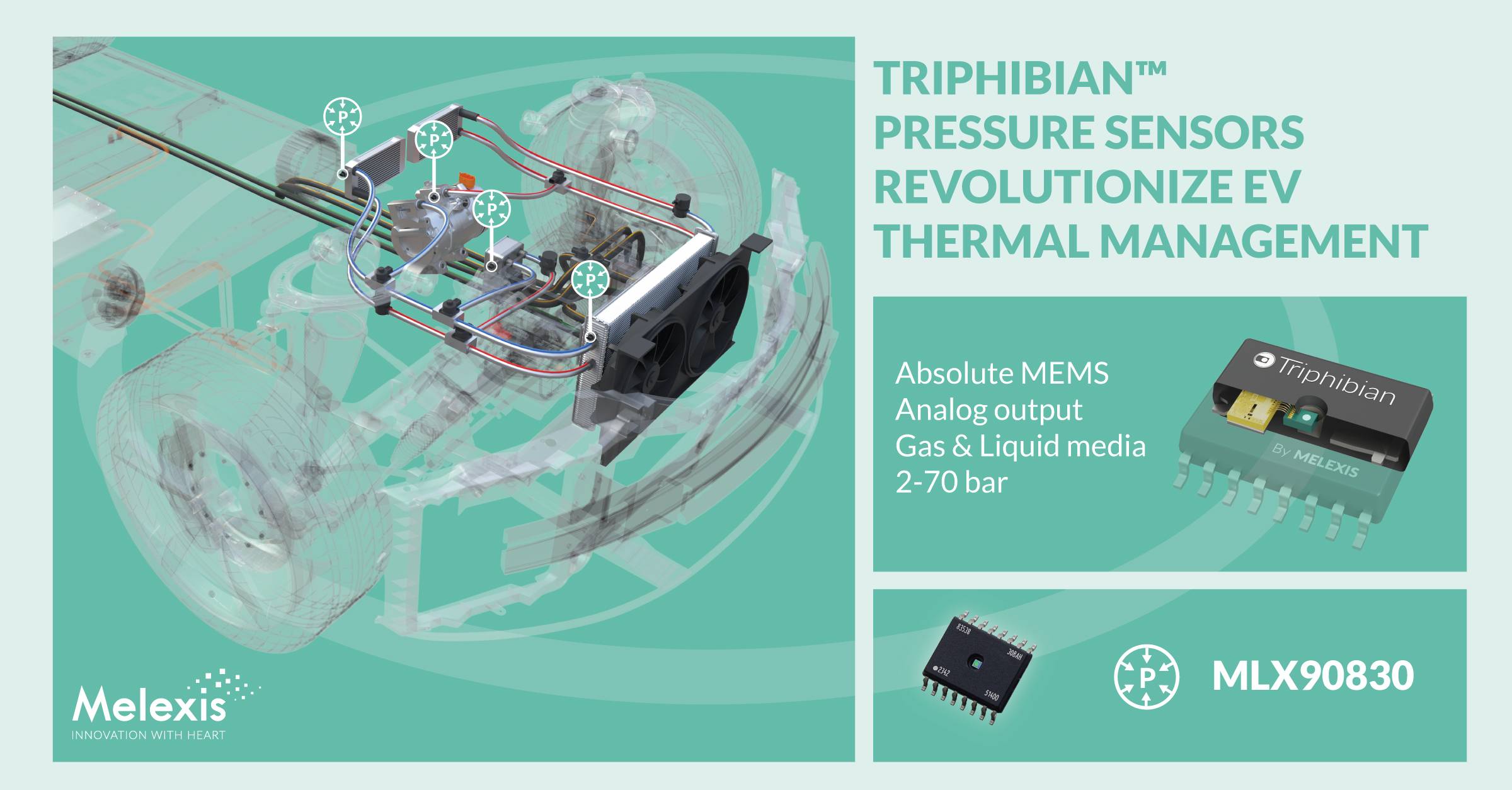

Melexis, a global microelectronics engineering company, announced today that it has launched its first Triphibian with a brand new patent? The pressure sensor chip MLX90830 for technology. This MEMS pressure sensitive element adopts an unprecedented miniaturization design, which can stably measure the pressure of gas and liquid media within the range of 2 to 70 bar. This device has been factory calibrated by Melexis and can measure absolute pressure while providing proportional analog output signals. The MLX90830 simplifies the integration of modules with the latest electric vehicle (EV) thermal management system, making the modules more cost-effective.

MLX90830 with Melexis Breakthrough Triphibian? With technology as the core, not only can MEMS (microelectromechanical systems) sensors achieve precise measurements far above 5 bar, but they can also achieve liquid contact measurement. The MLX90830 has a unique construction that achieves innovative breakthroughs, enabling both high-pressure sensing and compatibility with gases and liquids. The sensor chip adopts SO16 wide body packaging and is equipped with a hanging cantilever inside, with a sensing film at the tip.

The suspension cantilever design of the sensor chip provides a pressure peak immunity of up to 2000bar/ms and a static burst pressure level of up to 210bar. This device provides two pressure range calibration ranges by default (10 bar, 35 bar), each of which is tailored to the needs of electric vehicle thermal management systems, including low-pressure and high-pressure refrigeration circuits for refrigerants. Compared to the solution with exposed back, the design of MLX90830 is more robust, as there is still a pressure difference between the glass base side and the wire bonding side. In addition, the principle of pressure equalization is also applicable to cryogenic media, so the MLX90830 can operate under such conditions, which is the first time for MEMS pressure sensitive components.

Compared with existing non MEMS designs, the design accuracy of MLX90830 is higher and more robust, which helps optimize the efficiency of vehicle thermal management systems and can achieve longer driving distances. In addition, compared to independent sensor chip modules, its compact embedded packaging reduces the volume of sensor chips.

The MLX90830 includes sensors, signal processing circuits, digital hardware, voltage regulators, and analog output driver chips. The piezoresistive element implanted in the sensing film can form a Wheatstone bridge, thereby generating an output signal. After amplification, the signal can be converted into a digital signal, which is temperature compensated through 16 bit digital signal processing (DSP). Finally, an analog voltage output is provided through a digital to analog converter.

12. png

This sensor chip has advanced protection mechanisms that can prevent overvoltage (above+40V) and reverse voltage (below -40V), making it very suitable for large-scale vehicle applications. The MLX90830 is an independent safety unit (SEooC) developed in accordance with the ISO26262 standard, supporting ASIL B-level system integration to ensure compliance with the latest electric vehicle safety requirements.

"Based on Triphibian? Technology and accurately calibrated by Melexis, miniaturized MEMS pressure sensitive components can achieve centralized thermal management systems for electric vehicles, reducing system size and improving reliability." Pressure sensor chip product manager Karel Claesen said, "Customers can design the MLX90830 into independent pressure sensors or easily embed it into the system."

"With the help of Triphibian? Technology, MEMS sensor chips can improve measurable pressure levels and expand applicable media types." Senior Product Line Manager Laurent Otte explained, "Melexis has solved a problem that could not be solved by MEMS technology before. Now, we can open up new possibilities for applications in the automotive industry and other fields by measuring the pressure of liquid media."

About The Author

This is reported by Top Components, a leading supplier of electronic components in the semiconductor industry. They are committed to providing customers around the world with the most necessary, outdated, licensed, and hard-to-find parts.

Media Relations

Name: John Chen

Email: salesdept@topcomponents.ru